"Why are our suits considered higher-end compared to regular made-to-measure suits?"

- MTM Apparel Solutions

- Sep 25, 2024

- 2 min read

Updated: Nov 25, 2025

While many suits simply come off a production line, ours are different. We integrate extensive handcrafting into every garment to achieve the look and feel of a custom-tailored suit, but with the consistency and accessibility of a factory-made one.

We invite you to compare the following details with the suits you currently own. The difference in artistry and attention to detail will be immediately apparent.

1. The Lapel: Natural Roll vs. Stiff Glue

Many factories fuse the lapel with glue to simplify production and reduce costs. This creates a stiff, board-like appearance that prevents the lapel from rolling naturally and can lead to bubbling over time.

We reject this shortcut. Our lapels are meticulously hand-stitched to the canvas, whether you choose a half or full canvas construction. This technique allows the lapel to develop a soft, natural roll that gracefully conforms to the body. You can see and feel the difference: it's pliable, elegant, and built to last.

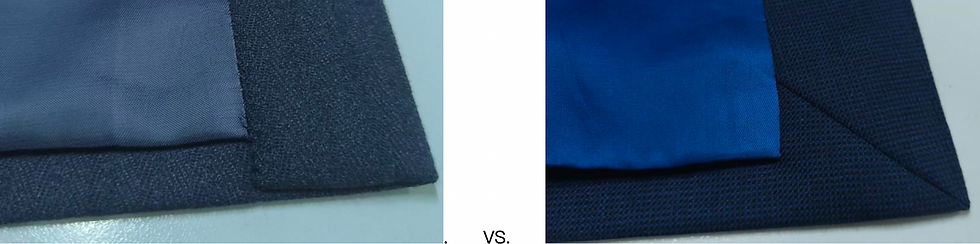

2. The Lining: Freedom of Movement vs. Constriction

A standard machine-stitched lining is rigid, pulling on the suit's outer fabric and restricting movement. It can also be difficult and expensive to alter.

Our solution is a hand-stitched lining. By attaching it with a loose, blind stitch, we create a "floating" effect between the lining and the shell of the suit. This provides superior flexibility and comfort, moving with you rather than against you. Furthermore, this method intentionally allows for easier, cleaner alterations in the future, protecting your investment for years to come.

3. The front panel: A Clean, Tailored Finish vs. An Unruly Flap

On standard suits, the bottom of the back panel is often stiffly machine-stitched. This can cause the front panel to "pop out" or flare awkwardly, refusing to lay flat against the body. If the jacket is too short, this construction makes lengthening it nearly impossible.

Our handmade finish ensures the front panel drapes cleanly and lies flat, providing a sharp, streamlined silhouette. More importantly, we construct this area with future alterations in mind. Should your posture change or a different fit be desired, the length can be cleanly adjusted, giving the suit a second life.

4. The Sleeve Vent: A Refined Opening vs. A Gaping Seam

Similar to the back panel, a machine-finished sleeve vent is often stiff and prone to flaring open, breaking the clean line of the sleeve. It also permanently locks the sleeve length, making adjustments difficult.

Our hand-finished sleeve vent is designed to lie flat and closed, maintaining a polished appearance. The button is functional, and the entire vent is constructed to allow for sleeve length alterations. This ensures the cuffs can be perfectly tailored to your wrist, both now and in the future.

While the hand-stitching defines the exterior, the true character of the jacket comes from within. We use only high-quality natural canvas and sculpted shoulder pads. Think of it as the difference between a building with a sturdy steel frame versus a flimsy one; our interior materials provide the structure that allows the suit to drape elegantly, mold to your body over time, and retain its shape for years

Comments